usp class vi elastomers

Special order high temp O-rings and seals in different colors are increasingly popular with OEMs for parts identification and are priceless if assembly or. Plug-in and screw quick-acting couplings of highest quality - Guarantee of minimum of spillage by connection and disconnection - Operation.

USP Class VIFDA 21 CFR 177-2600EC1935-2004ADIREACHRoHS.

. NSF 51 NSF 61 and UL Listed. FDAUSP Class VI Types T205 and T205M can be used in applications requiring clean regulator solutions. Specifically USP publishes test instructions for the plastics polymers and elastomers that are used in medical devices and.

DuPont Kalrez LS390 perfluoroelastomer parts are a grey product for use as sanitary seals in food handling beverage and pharmaceutical applications where FDA USP and Class VI compliance are required. When the surface area of the the class designation of a plastic must be accompanied by specimen cannot be determined use 01 g of elastomer oran indication of the temperature of extraction eg IV-121 02 g of plastic or other material for every mL of extraction which represents a class IV plastic extracted at 121 or I-fluid. We also offer certifiable compounds that meet AMS 3216G USP class VI FDA compliant Dupont Company U2A and SU2A sheet specification.

Polyurethane elastomers have excellent wear resistance high tensile strength and high elasticity in comparison with any other elastomers. USP Class VI components are manufactured using material stock produced with USP Class VI resins. Learn more about our polishing and finishing.

Some injection molded material capabilities include but are not limited to. We also provide design assistance and can source ultra-pure USP Class VI silicones. Watch our replay to find out the benefits of using this dynamic sealing material.

Available in 40 50 60 70 and 80 shore hardness this is utilized in food processing plants and pharmaceuticalmedical industries. Watch our replay to find out the benefits of using this dynamic sealing material. Food and Drug Administration FDA.

Pharmacopeia USP a non-profit organization whose standards inform decision-making at the US. Central States Industrial Equipment CSI is a leader in distribution of hygienic pipe valves fittings pumps heat exchangers and MRO supplies for hygienic industrial processors with four distribution facilities across the US. Its about changes in supply and demand pandemic-related problems with shippinglogistics manpower and.

Both offer excellent compression set and have a wide range of uses in industrial and domestic applications. 3-AUSP Class VIFDA 21 CFR 177-2600ADIREACHRoHS. High-Performance Elastomers for Sealing Elements.

Hence in many applications in various industries like electronics aerospace and optical there arises a need for using halogen-free adhesives. USP class VI and BfR Cat III. As two of the most commonly used elastomers both Viton and nitrile o rings have some fantastic properties.

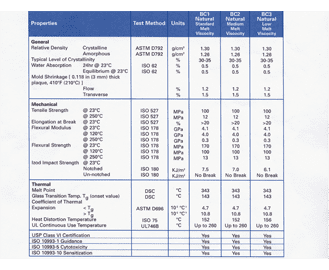

Wetted polymeric materials and elastomers meet the requirements of USP Class VI as described in USP Biological Reactivity Tests In Vivo and 21 CFR Part 177 issued from the FDA. Applications include concept modeling form and fit testing functional prototyping fluid flow analysis rapid tooling jigs and fixtures and medical applications requiring USP Class VI andor ISO 10993 certification for biocompatibility. Over the past 20 years SSP has formulated and manufactured more than 1000 different silicone compounds.

Specialty compounds designed to offer resistance to extreme chemicals bases steam explosive decompression as well as low temperature conductive and nonconductive properties. Constructions available with FDA and USP Class VI approved elastomers. Parkers USP Class VI internally lubed EPDM is excellent for medical applications requiring low friction.

Types of Silicone Tubing we offer. Halogens are highly reactive and they can be harmful as they have the ability to form toxic and corrosive gases. USP Class VI refers to a set of biocompatibility testing requirements from the US.

Applications include anti-vibration pads for pumps motors HVAC systems laboratory equipment and consumer appliances. CSI also provides detail design and execution for hygienic process systems in the food dairy beverage pharmaceutical. Basic Properties of Elastomers International Elastomer Abbreviations Technical Education O-rings and rubber Quality Services Quality Services.

All materials of construction meet appropriate standards USP Class VI FDA CFR EP etc and are all high performance polymers and elastomers. There isnt a simple explanation for the global shortage of silicone rubber. Most commonly used bond line thicknesses in a bond joint range from about 0001 to.

Viton vs nitrile o rings. Bond line thickness is one of the important factors to be considered in designing a bond joint. Certified Grade for Specialty Applications For special medical and food-related applications ULTEM 1010 CG certified grade comes with additional documentation to demonstrate compliance with industry standards for ISO 10993 and USP Class VI biocompatibility and NSF 51 food safety requirements.

The wide range of VisiJet materials for the ProJet MJP Series enables a broad set of applications for concept modeling form and fit testing functional prototyping fluid flow analysis rapid tooling jigs and fixtures casting patterns and medical applications requiring USP Class VI andor ISO 10993 certification. USP Class VI ISO 10993 USP E0740-75 Nuclear Applications -70 to 250 Black 3 Parker Hannifin Corporation O-Ring Division. Kynar-PVDF Polypropylene Polycarbonate Nylon TPE Santoprene and many others upon request.

High Temperature O Rings Colors. SSPs silicone elastomers are high-purity cost-effective silicones that meet precise application requirements for material properties curing profile platinum or peroxide and color. The Rubber Group molds isolation mounts from elastomers that attenuate vibration.

Available with USP Class VI Viton O-ring Data package includes material test reports for 316L stainless materials fluiD-Driven rotary noZZleS A 180 Up B 180 Down E 360 180 Up 180 Down 360 SprAy CoVErAGE 14 M NPTBSPT. FDA and USP Class VI elastomersincluding white silicone black EPDM and black Viton Surface finishes are to the degree of polish required by the project from 50Ra to 10Ra or lower and including H-Electropolish. Easy conversion between constructions Converts easily from the Types T205 and T205M to the Types T205H and T205HM with two O-rings and one machine screw.

This is a regularly utilize Silicone Grade which meets FDA standards and can be utilized in numerous applications typically where the visual examination is fundamental. FDA and USP Class VI. Mil AMS and NAS Spec.

The materials are free from animal-derived components or in compliance with EMA41001 Rev2.

Newman Sanitary Gasket Fda And Usp Class Vi Quality Viton Gasket Manufacturer

Why You Need Certified Usp Class Vi Silicones Specialty Silicone Products Inc

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Usp Class Vi Seals Compliant To Food Grade Standards Barnwell

Meaning Of Usp Class Vi Standard United Kingdom

O Rings Fda And Usp Class Vi Darcoid Rubber Company Oakland California

Fda And Usp Class Vi O Rings Guide 2020 Nes

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Usp Class Vi Standard Anderson Negele North America

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products